CO2

At least one fifth of the world’s largest public companies have committed to meeting net zero emissions. These commitments are

At least one fifth of the world’s largest public companies have committed to meeting net zero emissions. These commitments are

When you need to terminate high voltage or high current cable in a hazardous area, Abtech is the here to assist. Applications including umbilical connection, water injection and downhole pumps, fire suppression systems and temporary power connections are commonly found in an offshore environment.

Our MV & HV range is predominantly fabricated using 316L (1.404) stainless steel and is certified for Zone 1 and 21 hazardous areas. This ideally suited to operation in tough offshore conditions. The rugged nature of these products also makes them suitable for heavy industrial use where high levels of ingress and mechanical protection are required.

Details on our extensive range of enclosures for Medium and High Voltage termination can be found below. We also have a number of products where there is a requirement for high current connections.

The 4TJB can accept up to three single-phase connections (one conductor per phase) in either a bottom entry or through box configuration. The rugged enclosure is based on Abtech’s field-proven SX stainless steel junction box. It is DTS-01 deluge tested and fault rated to 40kA for one second.

The -125 variants offer a unique solution for the termination of offshore umbilical cables or onshore distribution systems. In this design, the power conductor compartment houses the HV cables. A separate control compartment is used for terminating fibre optic or control cables.

A thermostat-controlled heater can also be fitted to maintain a consistent internal temperature and prevent condensation build-up. The enclosure can be further configured with a sun canopy or painted to client-specific requirements.

The ABJB is manufactured from 316L (1.404) stainless steel. It is highly corrosion resistant and has been field-proven in some of the harshest industrial locations on the planet. Not only is the enclosure rated IP66 to EN 60529, it is also DTS-01 deluge tested.

As 11kV is the maximum allowable voltage under the IEC 60079-7 Increased Safety (Ex e) standard. The ABJB has been assessed in accordance with the Ex ‘s’, special protection concept (IEC 60079-33) and carries dual ATEX and IECEx certification.

In line with the lower voltage HVJB, an ABJB-125 variant is available for the termination of multi-use cables. In this design, the power conductor compartment houses the HV cables. There is a separate control compartment for terminating fibre optic or control cables. The allows work to be carried out on optical fibres or control conductors without a need to isolate the HV supply.

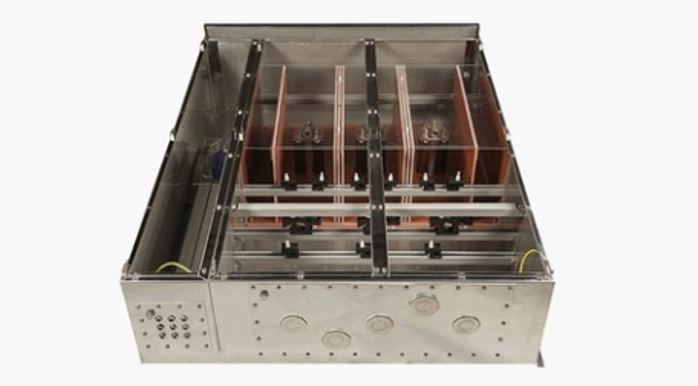

The HVJB range builds upon the proven SX stainless steel enclosure platform to provide a safe and flexible method of high voltage power termination and distribution. This provides the designers of electrical infrastructure with a greater choice of cables, configuration and termination.

The range can accept up to four phase connections, and up to three connections per phase. These can be done as either bottom entry or a straight-through configuration.

More the termination of combined, multi-use cables the HVJB-125 variant has been developed. This is a unique solution for the termination of offshore umbilical cables or onshore distribution systems. In this design, the power conductor compartment houses the HV cables. A separate control compartment is used for terminating fibre optic or control cables.

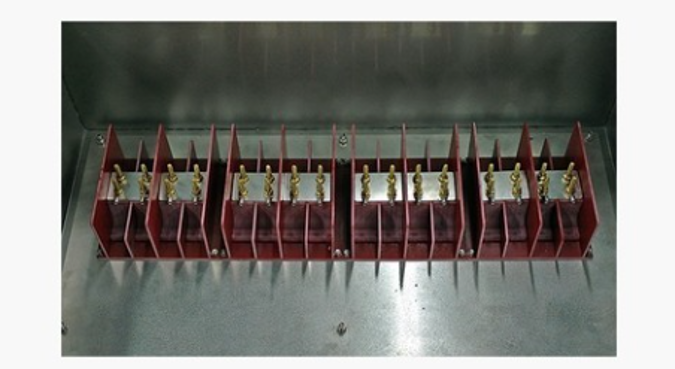

Designed to simplify the connection of 4.4kV to 8.8kV electrical supplies by converting conventional Ex-rated junction boxes into medium voltage enclosures.

Available in three, four and six-way configurations the terminal is both ATEX and IECEx approved. The MV can accept up to 240mm2 conductors and is rated for a maximum current of 250A.

MV Terminals can be specified to be linked in pairs or multiples and are suitable for high ambient temperature applications.

It is compatible with Abtech SX range stainless steel enclosures and suitable for high ambient temperature application of up to 130°C.